Call07971549793

Eva Foam Lamination

Product Details:

- Tensile Strength High

- Backing EVA Foam

- Feature Waterproof, Heat Resistant, High Adhesion

- Liner Release Paper or Film

- Temperature Tolerance -10C to 80C

- Design Printing No Printing

- Material EVA (Ethylene Vinyl Acetate)

- Click to View more

X

Eva Foam Lamination Price And Quantity

- 500 Meter

Eva Foam Lamination Product Specifications

- -10C to 80C

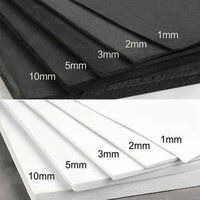

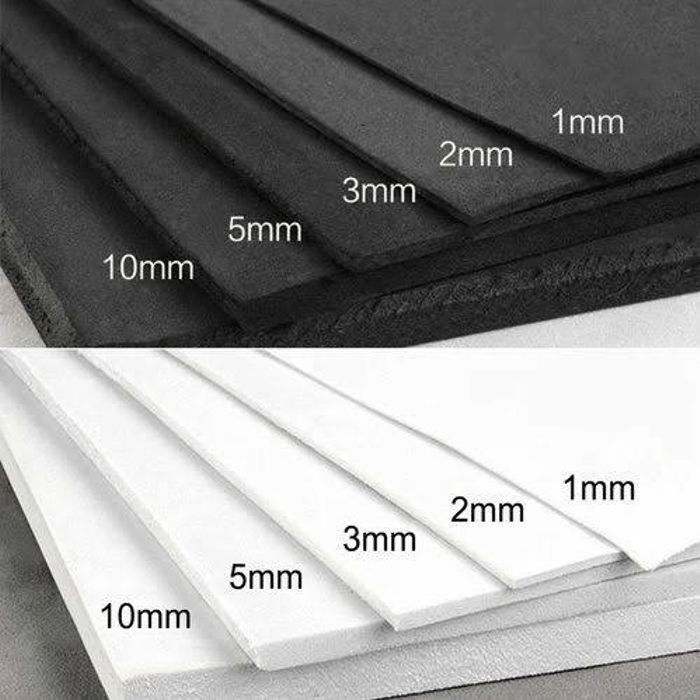

- 0.5 mm to 10 mm

- No Printing

- Acrylic / Rubber / Customized

- EVA Foam

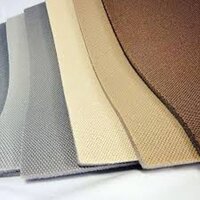

- White, Black, Grey, Custom

- Double Side / Single Side

- High

- 15 mm to 1250 mm

- 5 m to 100 m

- Waterproof, Heat Resistant, High Adhesion

- Release Paper or Film

- Pressure Sensitive

- EVA (Ethylene Vinyl Acetate)

Product Description

EVA (Ethylene Vinyl Acetate) foam lamination is a fabrication process that enhances the functionality and versatility of EVA foam by bonding it with various materials. Key aspects include:

-

Definition: Combining EVA foam with other substratessuch as fabrics, films, or additional foam layersthrough adhesive or heat processes to create composite materials.

-

Techniques:

- Adhesive Lamination: Utilizes pressure-sensitive adhesives (PSA) to bond materials, commonly used for creating adhesive-backed foam products.

- Flame Lamination: Involves passing EVA foam over an open flame to melt its surface, then quickly pressing it against another material to form a strong bond.

- Heat Lamination: Employs heat to activate the surface of the foam, allowing it to bond with other materials without additional adhesives.

-

- Adhesive Lamination: Utilizes pressure-sensitive adhesives (PSA) to bond materials, commonly used for creating adhesive-backed foam products.

-

Applications:

- Footwear: Enhancing comfort and durability by laminating EVA foam with fabrics for insoles and padding.

- Packaging: Creating protective inserts by bonding EVA foam with rigid materials to safeguard delicate items.

- Sporting Goods: Producing equipment like pads and guards by combining EVA foam with impact-resistant materials.

- Automotive Interiors: Improving aesthetics and comfort by laminating EVA foam with textiles for seating and paneling.

-

Benefits:

- Enhanced Durability: Lamination improves the structural integrity and lifespan of EVA foam products.

- Customization: Allows for tailored solutions by combining different materials to meet specific requirements.

- Improved Aesthetics: Offers a variety of textures and appearances through the selection of diverse laminates.

- Versatility: Applicable across various industries due to the adaptability of the lamination process.

Superior EVA Foam for Versatile Industrial Applications

Eva foam lamination delivers dependable performance for mounting, acoustic insulation, packaging, and sealing. Its robust physical structure provides high tensile strength and excellent moisture resistance, making it a reliable choice in diverse industries. Available in double-sided or single-sided tape formats, it serves well in demanding environments due to its heat-resistant and waterproof characteristics.

Customizable Solutions for Every Requirement

With options for tape thickness, width, adhesive type, and backing, this EVA foam product adapts to varied project needs. Offered in roll or sheet packaging, and colors including white, black, grey, and custom shades, every order can be tailored for optimal results. The foam is easy to store and handle, ensuring a smooth user experience from delivery to application.

FAQs of Eva Foam Lamination:

Q: How can EVA foam lamination be used in acoustic and mounting applications?

A: EVA foam lamination is ideal for acoustic insulation due to its excellent sound absorption properties. For mounting, its high adhesion and tensile strength provide reliable support, making it suitable for wall panels, fixtures, and equipment housings.Q: What advantages does EVA foam offer in terms of moisture and chemical resistance?

A: EVA foam lamination excels in wet environments, offering waterproof performance and resisting damage from moisture. It also demonstrates good chemical resistance against acids and alkalis, ensuring longevity and protection in demanding conditions.Q: When is the best time to use textured vs. smooth surface finishes?

A: Textured finishes provide extra grip and are suitable for sealing or cushioning applications where surface friction is beneficial. Smooth finishes deliver a sleek appearance and are preferred for mounting and packaging tasks that require a clean, uniform surface.Q: Where is this product manufactured and exported from?

A: Our EVA foam lamination is both manufactured and exported from India, serving global clients with high-quality materials and customized solutions.Q: What is the process for ordering custom EVA foam tapes or sheets?

A: To place a custom order, select your required density, dimensions, adhesive type, backing, and packaging format. Each order requires a minimum quantity of 500 meters. Our team will assist in finalizing specifications to ensure the most suitable product for your application.Q: What benefits does pressure-sensitive adhesive offer for EVA foam tapes?

A: Pressure-sensitive adhesives ensure strong, immediate bonding upon application with minimal effort. They work efficiently with both acrylic and rubber formulations, allowing the tape to adhere securely to a variety of surfaces without additional heat or solvents.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email